How To Become A Certified Machinist

This is because many employers look at GPA in order to determine if you have the correct competency and work ethic for the job.

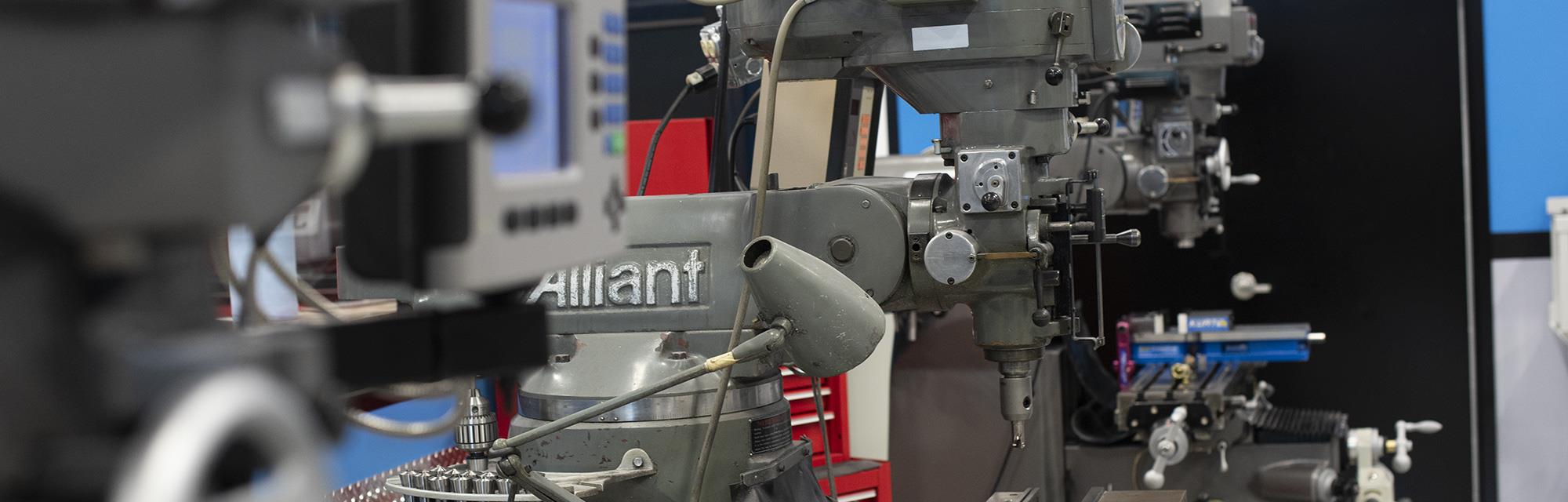

How to become a certified machinist. To become a CNC machinist there are a few routes you could take. CNC machine work is highly technical and requires significant training and preparation. Possesses the technical skills to enter the workforce or go on to further education.

APPRENTICESHIP PROGRAM An apprenticeship training program consists of on-the-job and in-school training. Generally the time-frame to become competent in the trade of General Machinist is 8000 hours approximately four years consisting of 7280 hours of on-the-job work experience and 720 hours of in-school training. Utilizes critical thinking and various approaches to problem solving.

To review with a high school diploma 4-5 years apprenticeship and possibly certification tool and die. Instead candidates are required to complete a training program first and then apply for a position. Contact your states trade licensing office and inquire about a machinists certification.

To become certified a candidate must pass both a theory exam and a practical exam. Prepare a sample appraisal report that conforms to guidelines set forth by the Uniform Standards of Professional Appraisal Practice USPAP. A high school diploma or GED is a minimum requirement but there are other ways to gain an education in the field.

For detailed information about this program see the apprenticeship training standard. Demonstrates professionalism through leadership a strong work ethic and teamwork. You may find that experience in other jobs will help you become a master machinist.

Employers usually require machinists to hold a high school diploma or equivalent. Some will get you there faster than others. There are many different paths someone can take to become a certified CNC machinist in the USand a degree is not necessarily required but certified skills and training hours generally are required.