What Are The Five Safety Precautions Use In Machine Workshop

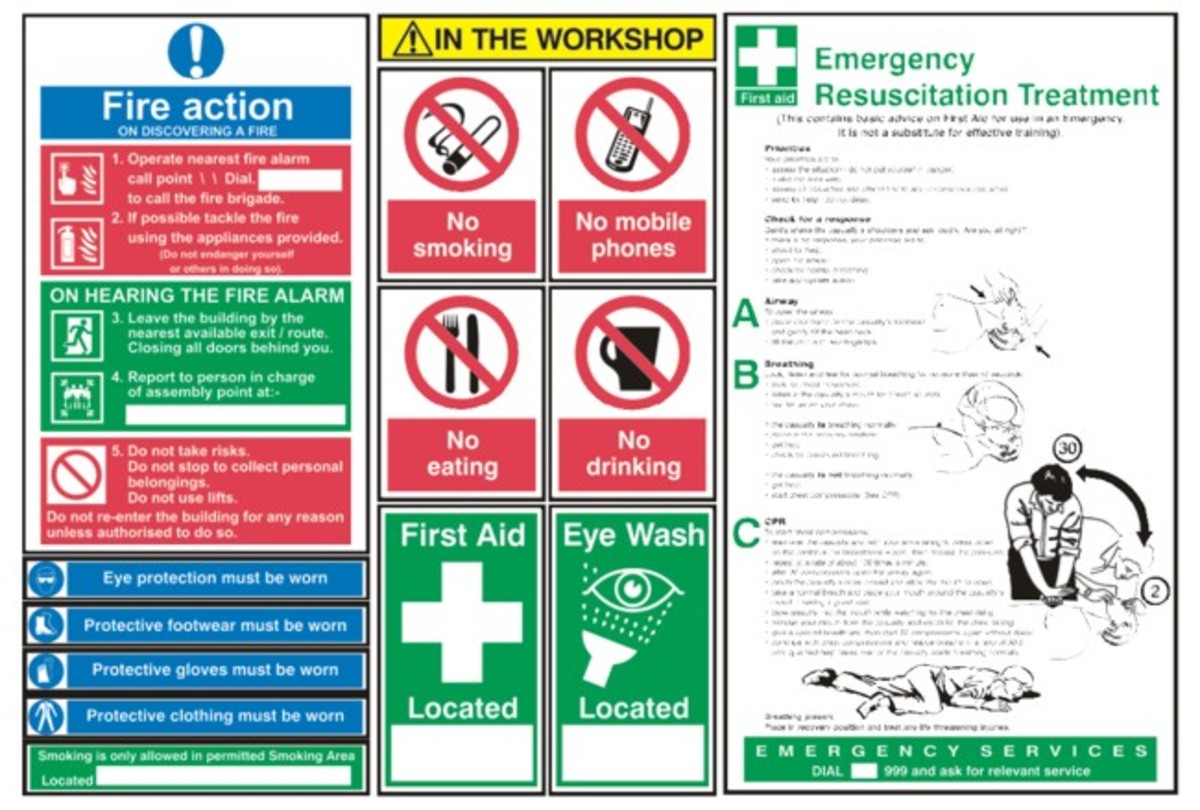

Shop Safety Checklist Safety Checklist Checklist Safety.

What are the five safety precautions use in machine workshop. Many are blaming themselves today because of the problems they had due to their carelessness in workshops. Never use hands to remove chips and curls. Machine Safety at Carleton.

Types of Safety precautions while working in an industry workshop with tools and machines. Always stop machine for cleaning chips and curls. Use the supplied chip brushes and rags to clean machinery.

Safety Precautions Always Wear Approved Safety Glasses Rollup Sleeves Remove Tie And Tuck In Looseclothing Never O Lathe Machine How To Remove Lathe. This will embed particulates into the precision machine parts and will drastically reduce the life of the machine. This guide is an introduction to managing the risks associated with use.

Safety Tips For Confined Space Workers In 2021 Health And Safety Poster Safety Training Safety Tips. Adjust the upper guard assembly to within ¼ inch of the stock prior to starting the machine. Always stop the machine for making measurements and adjustments.

Wear shirts or uppers with sleaves cut off or rolled. Dont wear neck ties or loose turn clothing of any kind. Untidiness Overcrowded passageways objects on the floor grease or oil on the floor.

Health and Safety Executive Working safely with metalworking fluids A guide for employees 1 of 5 pages Introduction This leaflet aims to help employees who work with metalworking fluids understand the main risks to their health. Specific safety guidelines for some of the machine process like lathe drilling shaping planning slotting grinding milling and finishing operations are also described in the following. Electronics Curiosities July 02 2021 Definition- Precautions are taken to prevent general and other accidents occurring inside the workshop are called protective precautions.