Types Of Holding Tools In Workshop

90 minutes to 3 hours.

Types of holding tools in workshop. The vises provide the quickest and most efficient set up method for parallel work. Dies are made either solid or split type. Above is a picture that displays an example of me using this tool.

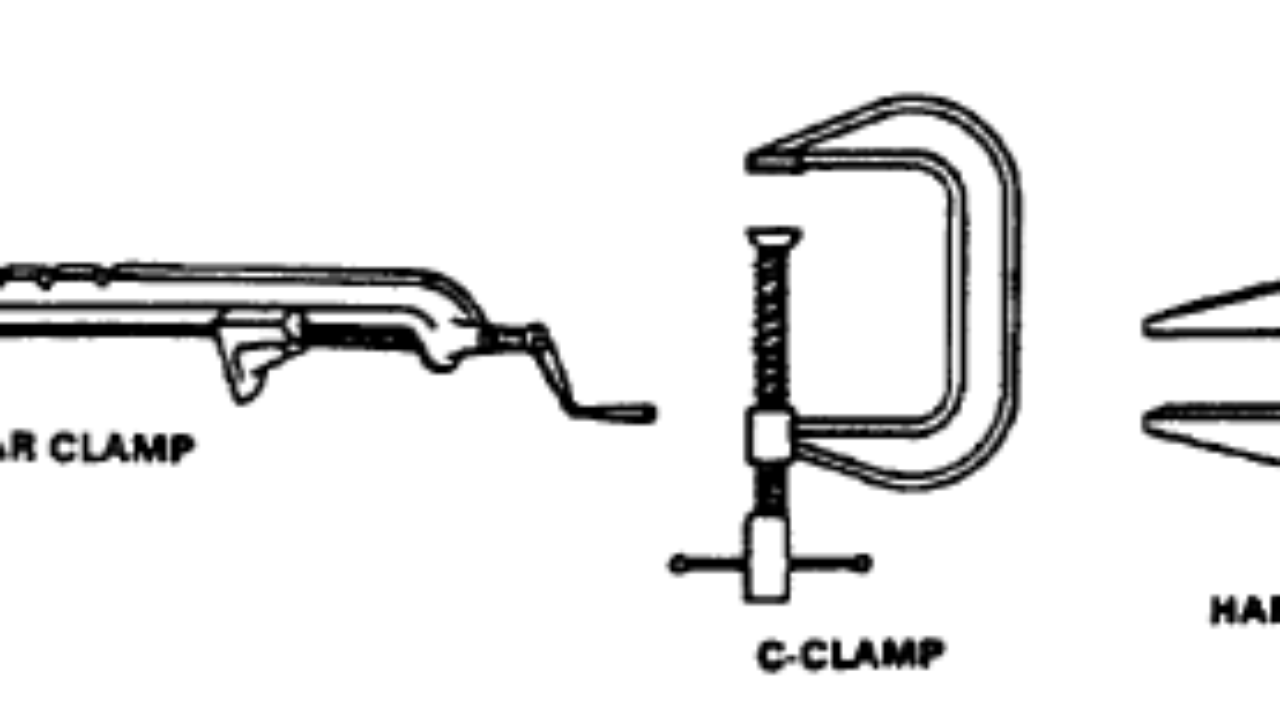

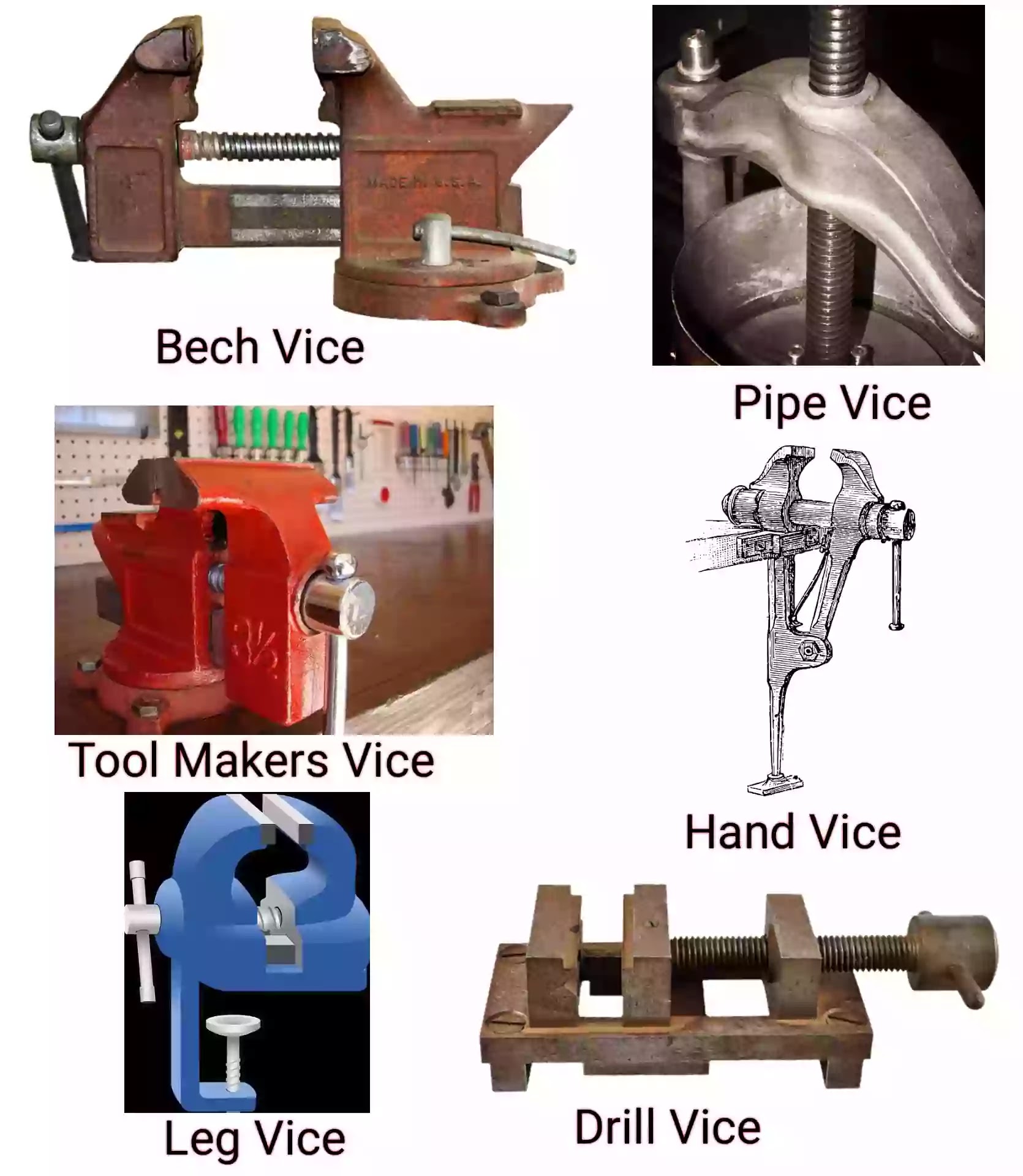

Center Punch The Detailed Explanation of Marking Tools was HERE 3MEASURING TOOLS Used in Fitting. Vice is a job holding tools and types of vices used in workshop are Bench VicePipe ViceTool Makers ViceHand ViceLeg ViceDrill VicePin Vice. Holding tools are also known as Work Holding devices in the Fitting workshop.

At this length a workshop can begin to address ideas and concepts in some depth and teach some skills. A4 Machinist vise is a work holding tool for machining activity. Available in many sizes.

Drill vise is a holding device used for clamping most workpieces while drilling. Every holding tool is used to support and secure a piece of material. One of the most commonly used work-holding devices is also called a drill press vise.

Common concepts in schools with Holding tools. The greater the pressure applied to the handle the tighter is the work held. They are 3 types of Marking tools used in the fitting workshop and are as follows.

Friction-free unlike hammers and lever bars these hydraulic wedges limit any damage to the joints. The body of the vice is made of cast iron while the two clamping jaws are made of hardened tool steel. Dies are the cutting tools used for making external thread.