How To Make Your Own Cnc Wood Router

A set of metric and imperial hex keys 316 and 5.

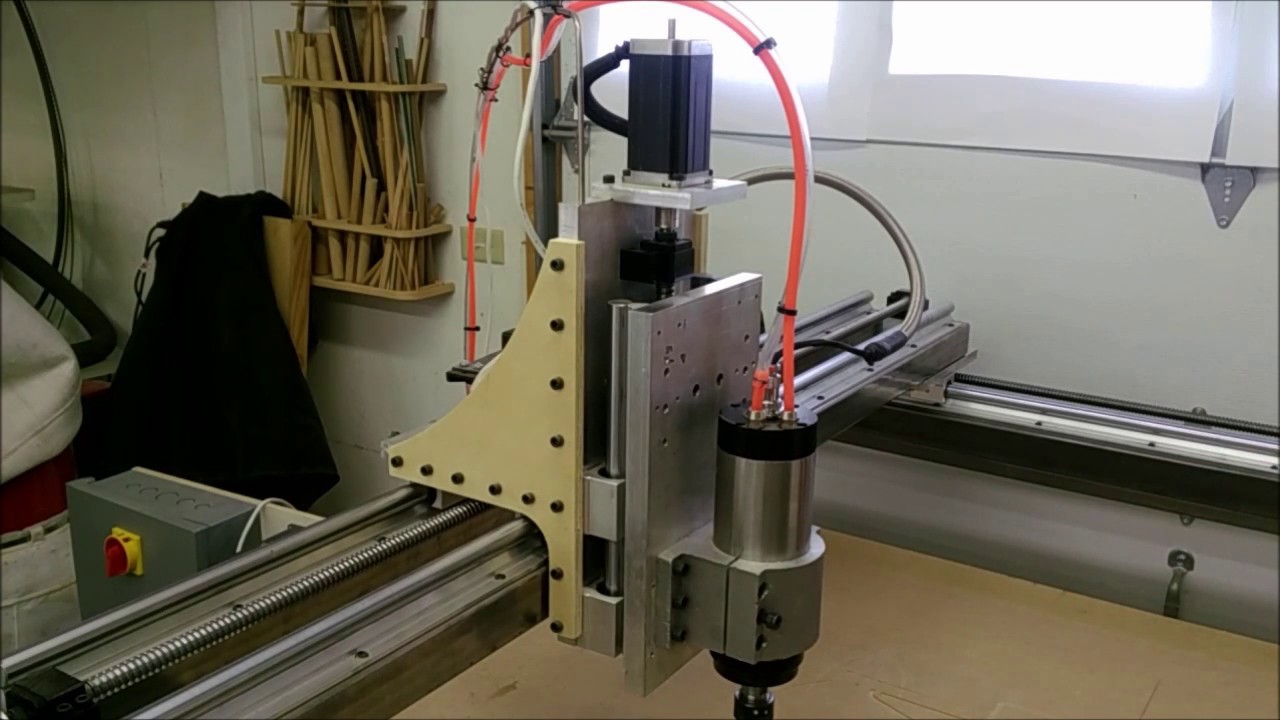

How to make your own cnc wood router. Most importantly leverage your new and existing offline connections to get more clients. Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router.

Drill and tap some mounting holes in the edge of each bearing and. For homemade CNC routers drive screws are most commonly used. What kind of linear drive system will you use for each axis.

Almost every CNC router hobbyist can create this wonderful project without the need for engraving metal parts. One of the first tweaks to the design was the drag chain shown above that keeps the wires organized and out of the way. This is how I built myself a CNC router from wood that can even machine metals Support me Patreon.

The main thing to note while preparing the digital image is to remain consistent with any adjustments you make. Get a website as soon as you can and run a few paid ad campaigns. For just a few dollars the student who built this machine was able to make a huge improvement to the look and performance.

Like many CNC router projects the wood needs to be flat and sanded down with grade 180-240 sandpaper. If the machining precision has some gap with the standard it may effect the instruments function. This design can be amended and would suit machines from 2400mm x 1200 down to 1200 x 900mm.

CNC wood router can make many instruments like piano guitar violin and others. A chop saw wood lathe drill and a drill press and finally a table saw nothing fancy but now with the CNC router he has a world of possibilities for projects. To make a bearing out of plastic just drill a hole the same diameter as the corresponding shaft.