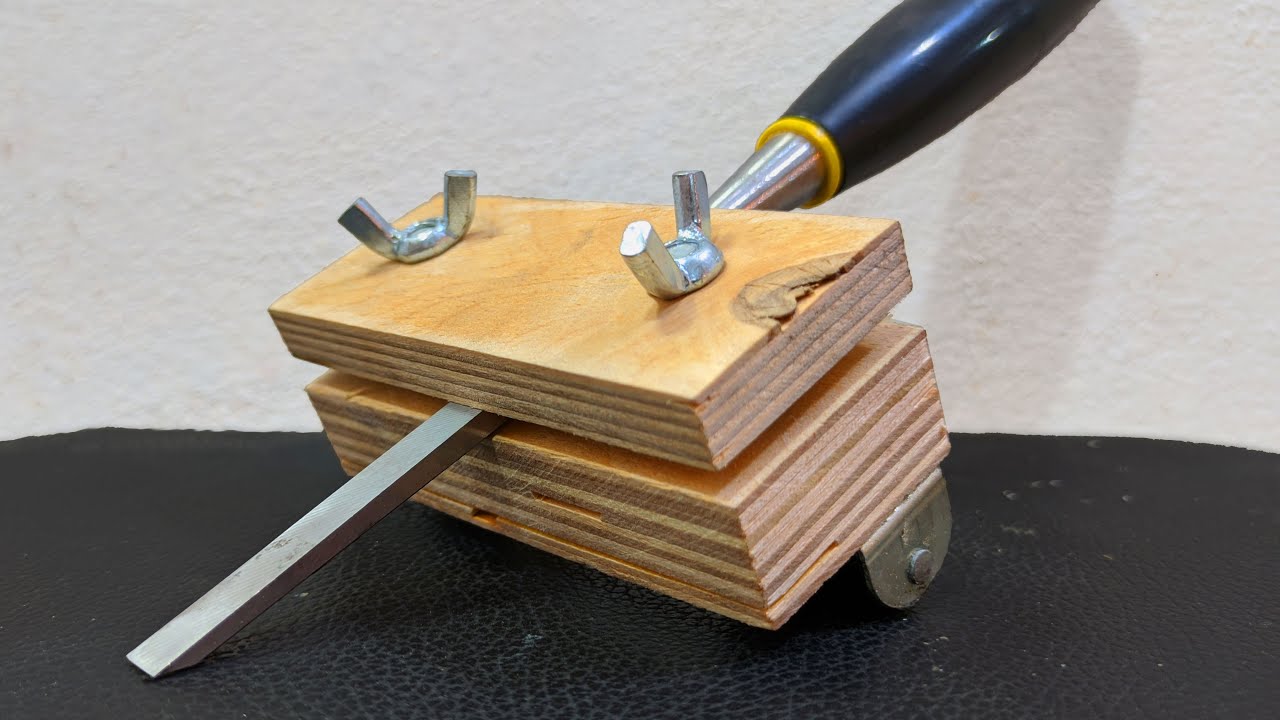

How To Make A Plane Blade Sharpening Jig

Now affix the level to the back of your chisel or plane iron and clamp them inside your honing guide.

How to make a plane blade sharpening jig. The side is very important component because it is what you will use to make sure your blades are set at 90 degrees in the sharpening jig. The screws are tightened to clamp the blade and loosened to remove it. You sharpen the blade by regrinding the bevel.

With the sole face down rub it back and forth on the coarse diamond sharpening plate. Indexing the jig The best tool for indexing the protrusionangle number is a square digital level. I used it t.

As a general rule of thumb. Check the sole surface again using the light and the straightedge. The main danger is overheating the metal and damaging the temper.

Flatten the Back of the Planing Iron on Diamond Stone. You can just turn a knob and it will steepen the angle for you and create a micro bevel using the 8000 grit stone only. Flatten Your Glass or water Stone.

Cut the front and back side at the steepest angle intended for grinding. First find a flat surface to work on lay the level on it and calibrate the level to zero degrees. The first step is to have a minimum of 2 sharpening stones.

Make it shorter than your shortest chisel blade here about 10cm. Sharpen Bevel in Honing Jig Stone and Glass stone Use Ruler Trick. My sharpening jig is made out of pieces of wood which will help hold the plane iron blade at the correct angle of 30and 28.