How To Make A Parting Tool Holder

Not sure of type.

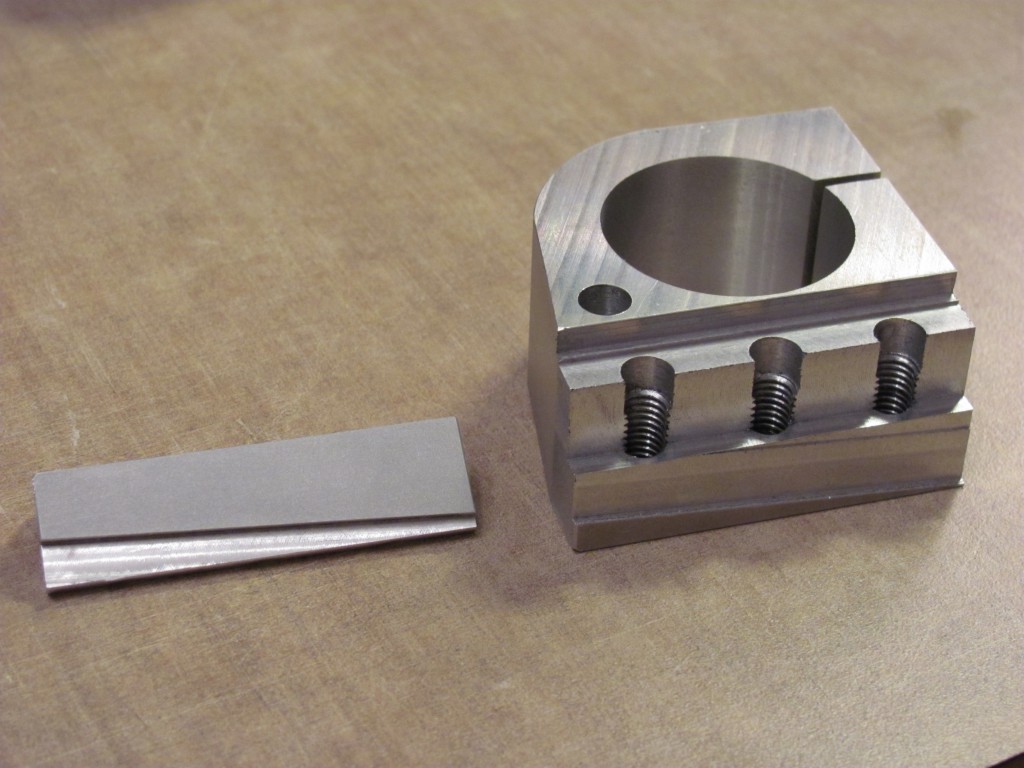

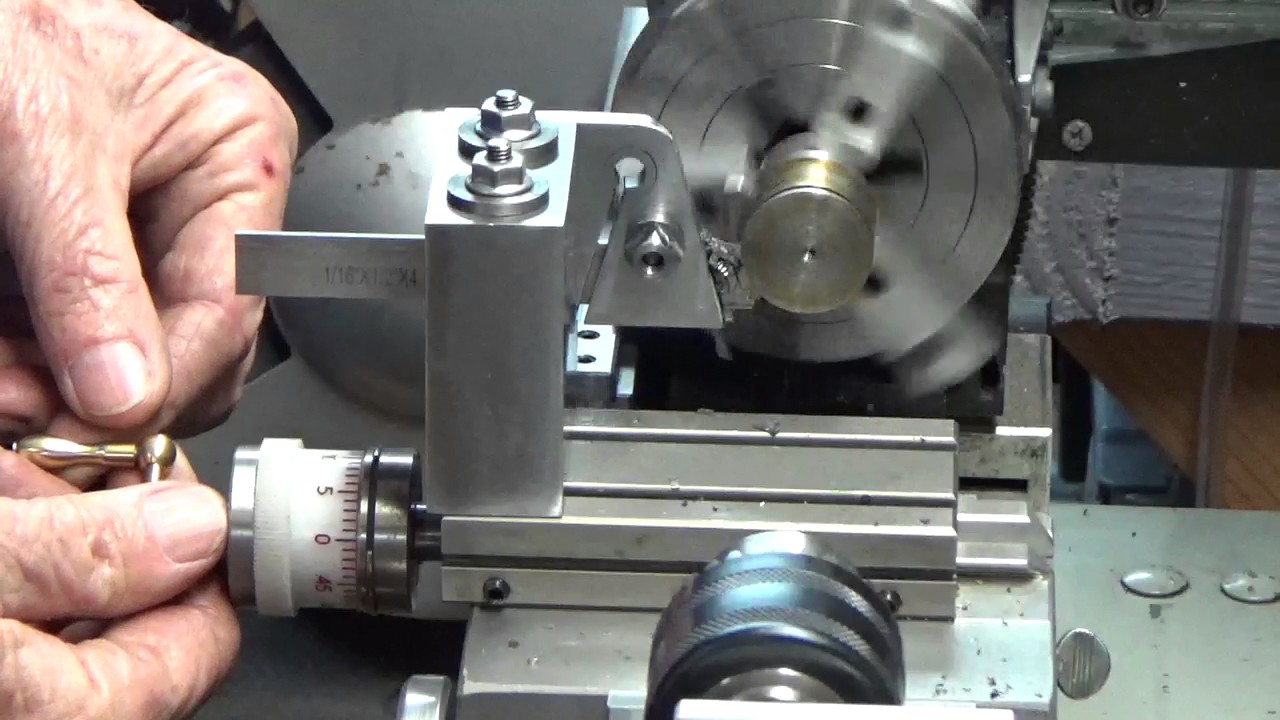

How to make a parting tool holder. Facingturning holder but holds the parting blade inverted. For small part machining use an insert with the smallest width and sharpest cutting edges. Set up in the four jaw chuck with the front wedge hole running true center and drill out to just under 34 bore to 34.

The easiest thing to use was a part. The blade holder and a bar I milled and drilled and tapped 14-20 to bolt to the blade holder. I needed a parting tool that would give a little so I based my design on designs I found on the internet.

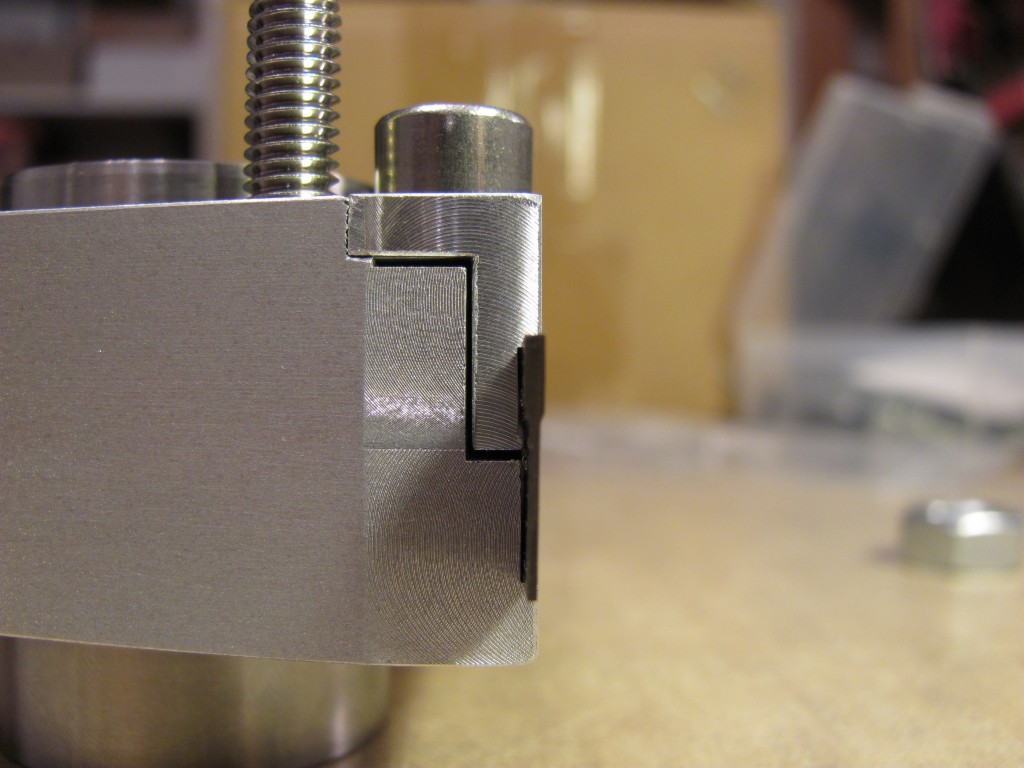

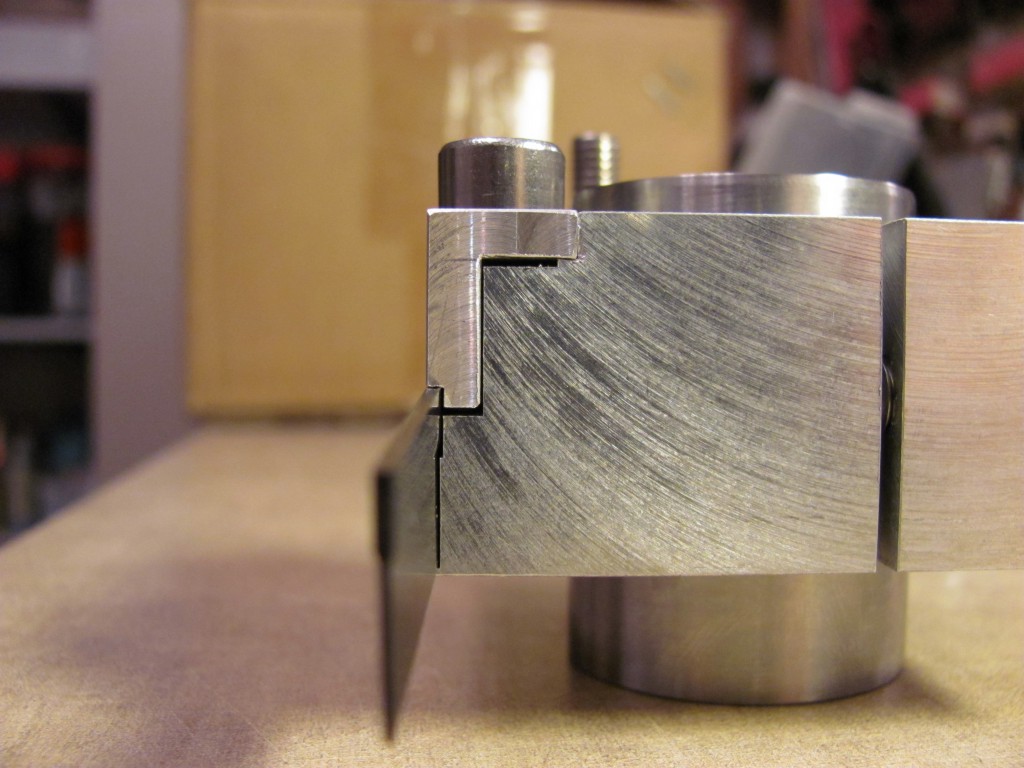

Another important step is to make sure the cutting tip of your parting tool is right on the center line of the piece you are parting. Cut the slot then remove the shims and enlarge the slot. Behind the scenes of Y-axis parting.

I really enjoy making my own woodturning tools if for any reason just to see if I can do it. Leave one side with no slot. Make sure your tool is.

I find that locking my carriage is an essential step to take in order to maximize rigidity. With the tip of the tool just beyond the surface of the workpiece turn on the lathe. This is two parts.

Even better if you have made a carriage lock use it. Parting cuts should be made at low speed. If superior tool edge sharpness is not necessary choose a 3-edge or 2-edge insert for a more economical solution or for larger diameters.