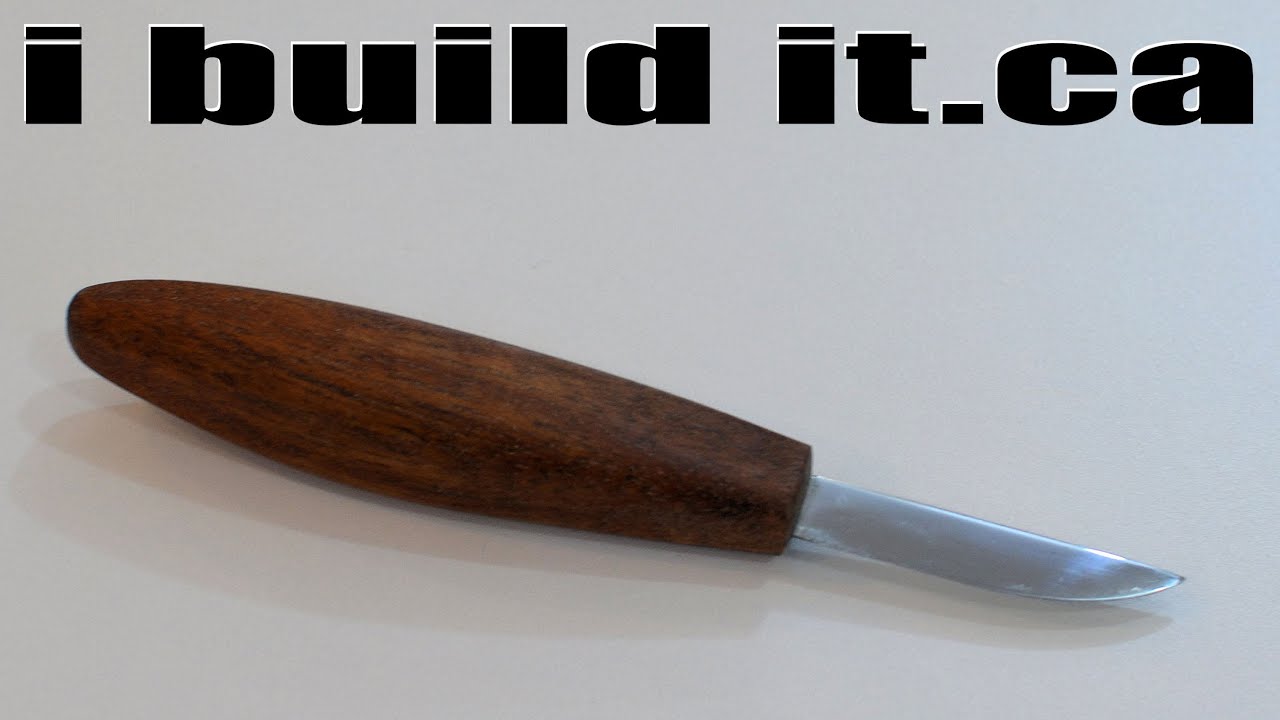

How To Make A Homemade Carving Knife

Start with a 36 to 60 grit sanding belt and finish with 180 or finer.

How to make a homemade carving knife. Staple the folder on the top and along the open edge at one inch intervals. This video will show you how to make a wonderful carving knife from repurposed metal and some scrap wood. Checking the hardness after I found a file would not cut into the blade so the procedure was successful.

Cut a 15cm thick slice of your log. 450 for 30 minutes let it cool to room temp and do it again. Nordic Verdant Knife Materials.

Kent Andersson Damascus steel. Now fine shape the end that you plan to hammer the blade into. Leave the bottom open to slide in your knife.

When the blade first sits into the wood it is very hard to work that area without damaging the blade and the edge of the carving knife. A mixture of Boiled linseed oil and bees wax is used to seal and protect the wood. I then checked that the tang of the knife fits in the shape of the cut that I just made and made minor adjustments to the shape on the grinder.

Set the knife down on your drill plate with the tang facing up. I then cleaned the oil off of the blade and put it in the oven at 400 degrees for about 20 minutes this tempers the blade to relieve stress and reduces the hardness of the blade slightly. Cover the blade with blue tape while you shape the handle to your liking.

Keep the blade cool by dunking it in water when you grind them and youll be fine. Split it a few times and with the ax roughly cut the handle into shape. I put the blade in my table saw the homemade one and cut a bit off the edge of some wood.