How To Grind A Lathe Parting Tool

My most immediate need is to grind a single point cutter for ACME threads.

How to grind a lathe parting tool. I intend mostly to use them for roughing and for preliminary grinding of reliefs on drills. In this example we are making a normal right handed tool for the lathe. Turn the grinder on and lower the tip of the parting tool onto the moving grinding wheel for a few seconds.

This is easy to do using a diamond sharpening tool. This video covers how to properly grind the tool how to set the tool so it is ri. Being excited I went to the wood lathe to try out the new parting tool.

Sharpen square- or round-nose scrapers on a bench grinder. Simply turn the wheel on and draw the tool across the surface of the stone. What you dont want to do is grind rake into the top of the blade.

So all you have you to do is set your tool rest on the grinder up for a 50 degree angle grind. For our second project we were given two new 38 lathe bits and had to learn to grind a turning tool parting tool facing tool and a threading tool for 34-10 ANS threads. Position the tool rest 10 from horizontal to grind an 80º bevel on the blade.

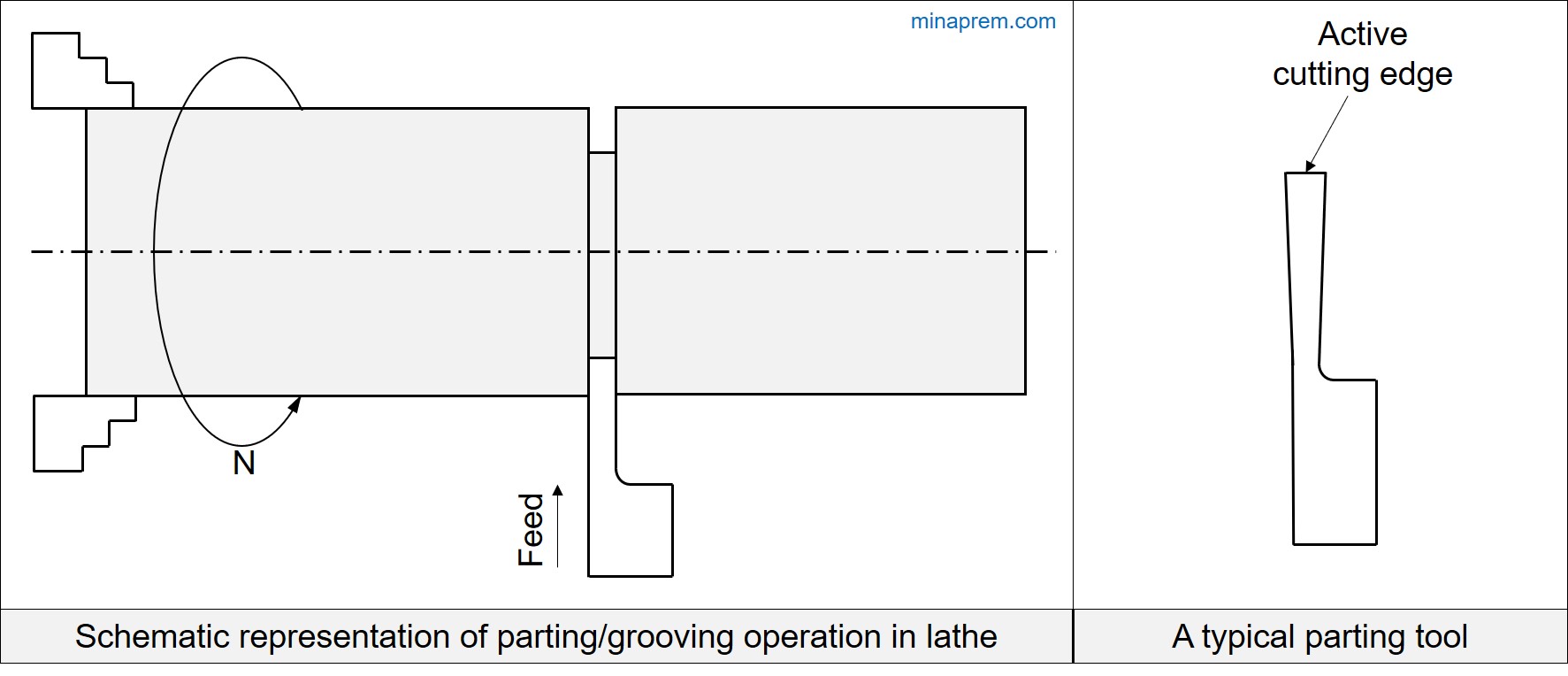

To be clear the back rake angle on the P-parallel bits is best controlled by the choice of tool holder. If using an indexable part-off tool check that the cutting insert is in good condition. Parting is one of the most misunderstood machining operations on the lathe.

45 is a good general angle. You can use whatever back rake you like if you achieve it by angling the entire blade like the Aloris holder. Lightly touch the tool to the wheel and then swing a round-nose tool Photo A or slide a square-edge one Photo B against the wheel maintaining the end contour.