How To Charge For Cnc Plasma Cutting

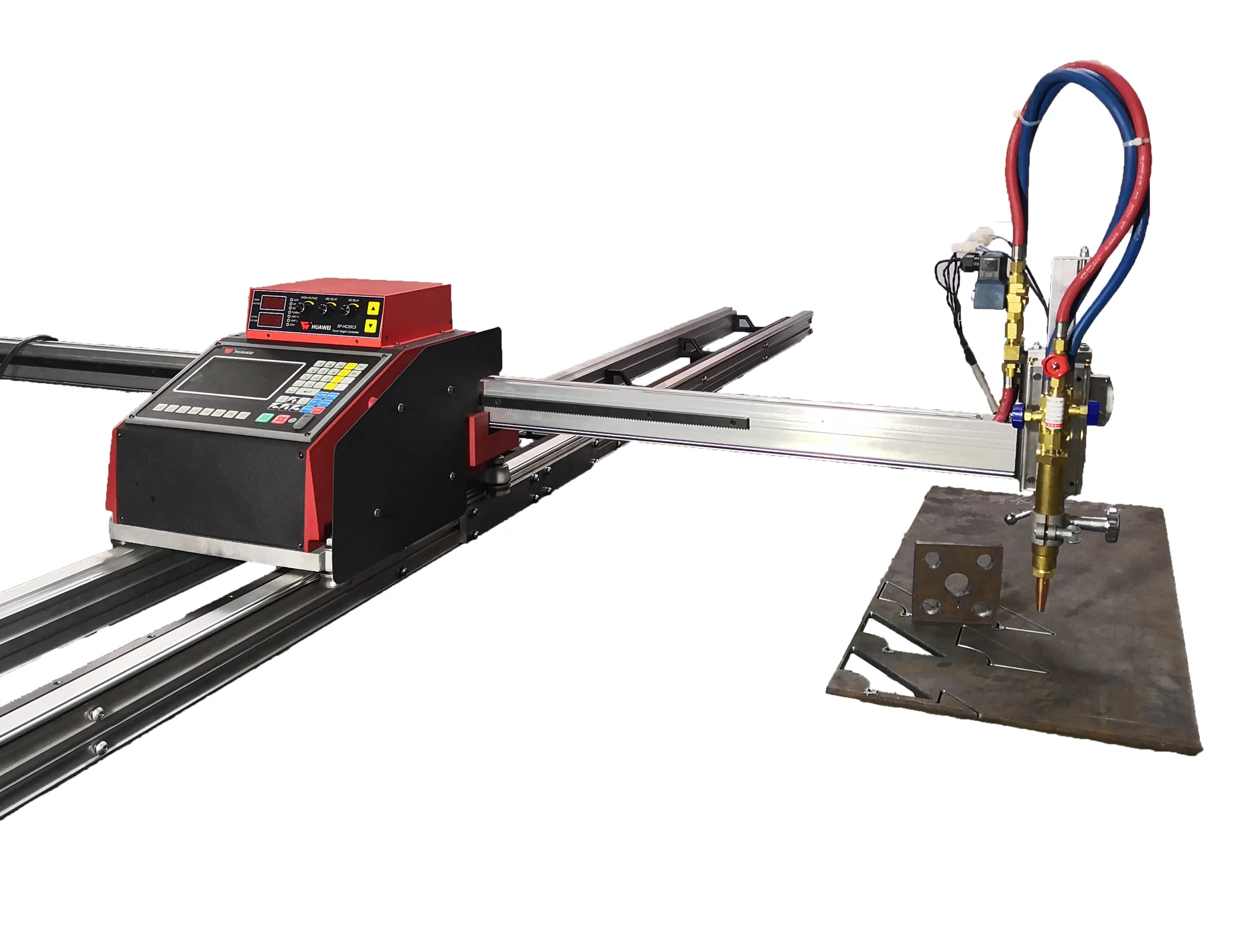

Enter the joggle state move the cutting device to the left the machine moves to the parking position and turn off the power of the controller.

How to charge for cnc plasma cutting. Pricing CNC plasma cut parts This is a topic that comes up on a pretty regular basis on the groups and forums. It receives the electric charge from the cathode and focuses it on producing an arc. Most shops will charge per machine 2-3 times labor rate for the machine operated so if the typical plasma set-upoperator makes 20 an hour in your parts the rate charged out will be 40-60 an hour.

2 Plasma O 2 Shield 30 A Cutting 220173 220194 220313 220180220193 220192 Pierce complete is recommended for these thicknesses Note. When completing the cutting process close the air compressor. Most mechanic shops are 80 to 120 an hour.

After five minutes turn off the plasma power and turn off the control system power. The nozzles with a more massive mouth can create metal gouging and the nozzles with the smaller mouth can make smooth cuts. Every area of the country is different.

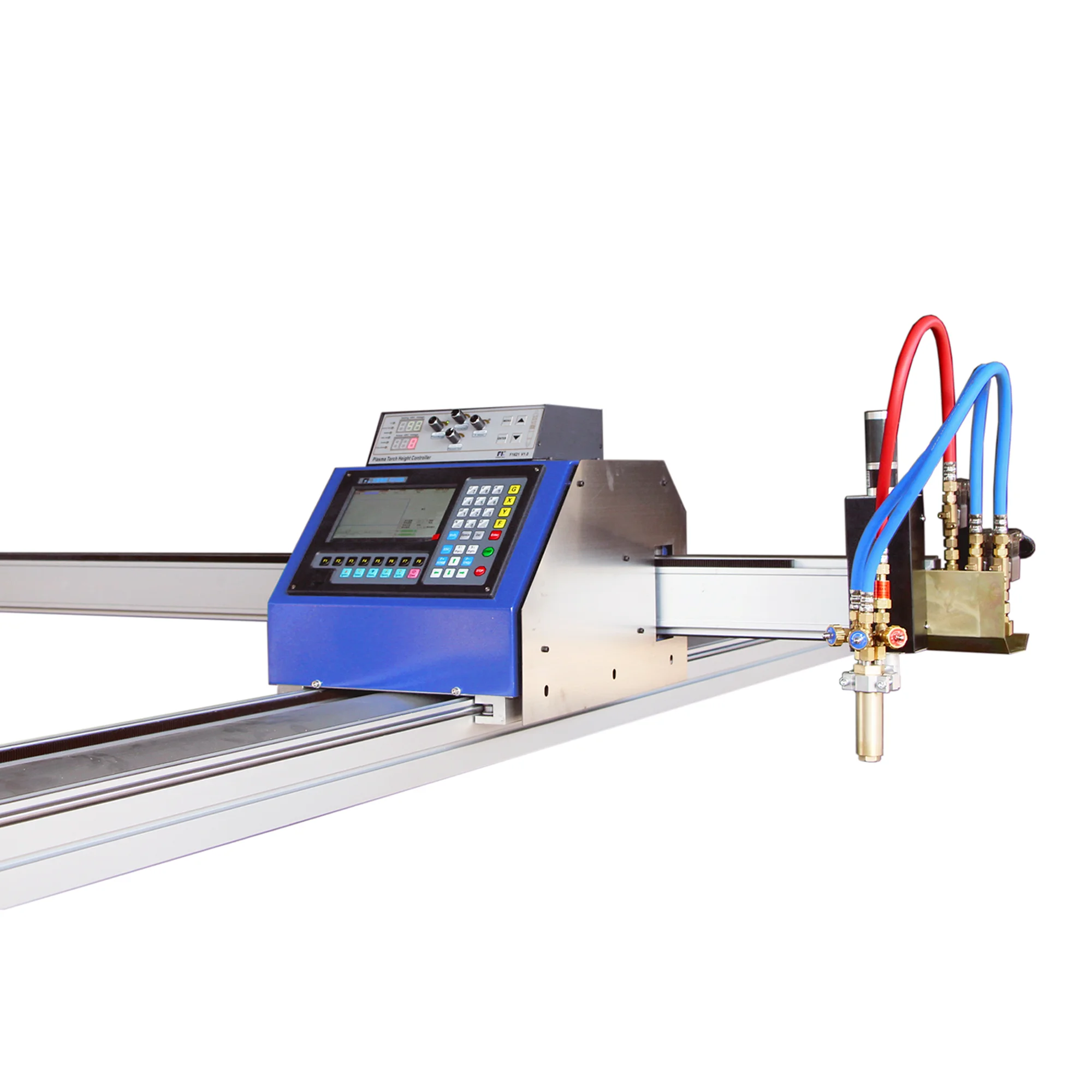

How to Set Up and Use a PlasmaCAM CNC Plasma Cutter. Luckily there are strategies to make the process easier and more reliableLets t. Ive got no idea how much to charge is there a going rate.

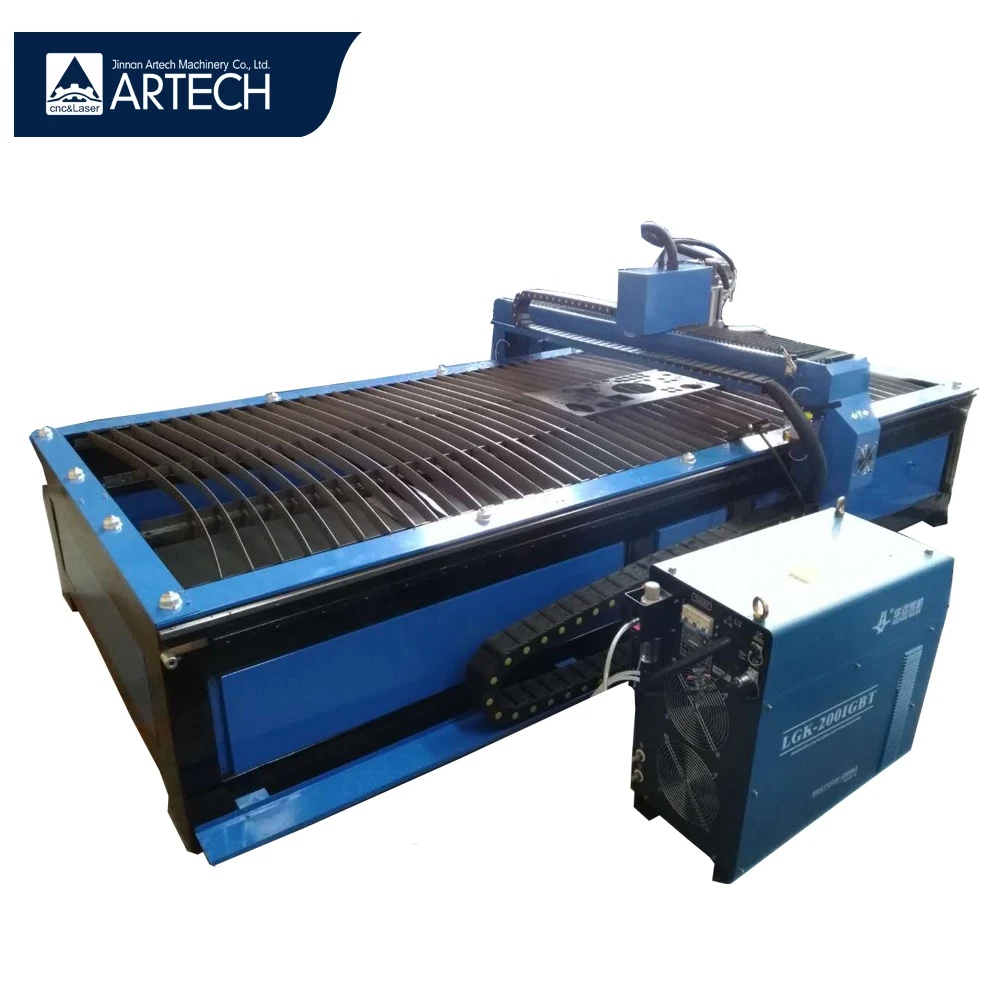

Metal Form Group offers fast efficient metal cutting with the Plasmacam Samson 510 CNC Robotic Plasma Cutting machine with a cutting table capacity of 3000mm x 1500mm machine which is suitable for full sheets. If you have a bolt hole you want it to cut inside the line so the hole is cut out. The PlasmaCAM is similar to other production models and is fairly easy to use once you get.

If youre making a part you will want it. Any advice greatly appreciated. I have found that this is a great and easy way to quote.