How To Build Cnc Wood Carving Machine

Most kit manufacturers will also offer a number of customization options.

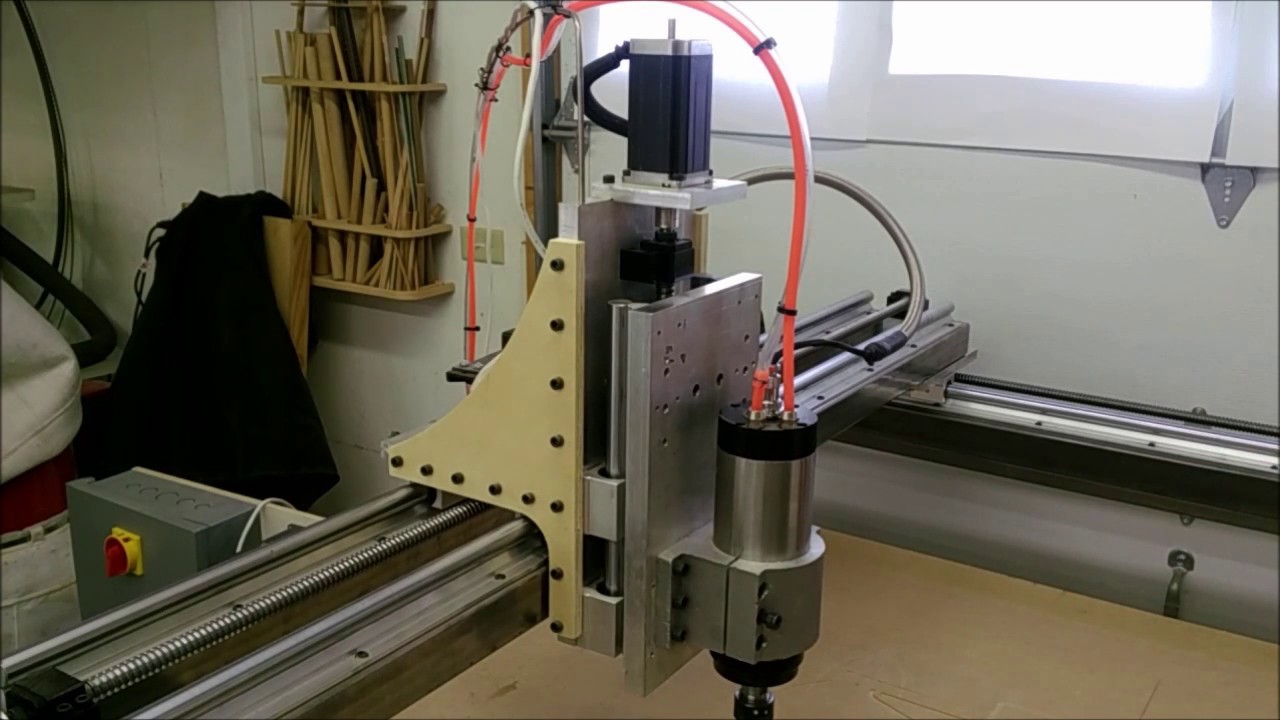

How to build cnc wood carving machine. For example all CNC routers will go back and forth and up and down but some have even more control and could for example turn the bit to 90 degrees or more to actually make three dimensional items. The sliding allowed adjustment of width. It is defined as a machine that is controlled by computer software.

After long hours of research out how a CNC wood carving machine directly from the manufacturer functions was finally figured out. Because of how this CNC wood carving machine takes woodworking to another level a lot of investigations were carried out. That material can be anything such as wood aluminum or steel.

The CNC wood carving machine works according to the same principles. Ad Your parts for less and without effort. There are a number of different types of CNC machines and they have different capabilities and sizes of wood that they can accommodate so there can be some restrictions.

Load the CAD program on the computer and become familiar with how to use the software. Thats because a kit generally comes complete with everything you need to put your machine together and get started with making things. One the CNC machine begins executing a command it begins removing material.

Top 3D printing HP5210 MJF and 3D Systems 6100 - CNC with ultimate Hermle and Mazak 5axis. I had to drill larger holes in the steel tube tops for screwdriver access. Create your wood designs so they are ready to transmit either to a printer or cutting machine.

Top 3D printing HP5210 MJF and 3D Systems 6100 - CNC with ultimate Hermle and Mazak 5axis. Ad Your parts for less and without effort. I used 1 by 2 inch steel tubing bolted on top of 3x1 inch 80-20 aluminum for the underlying frame.