How To Build A Cnc Woodworking Machine

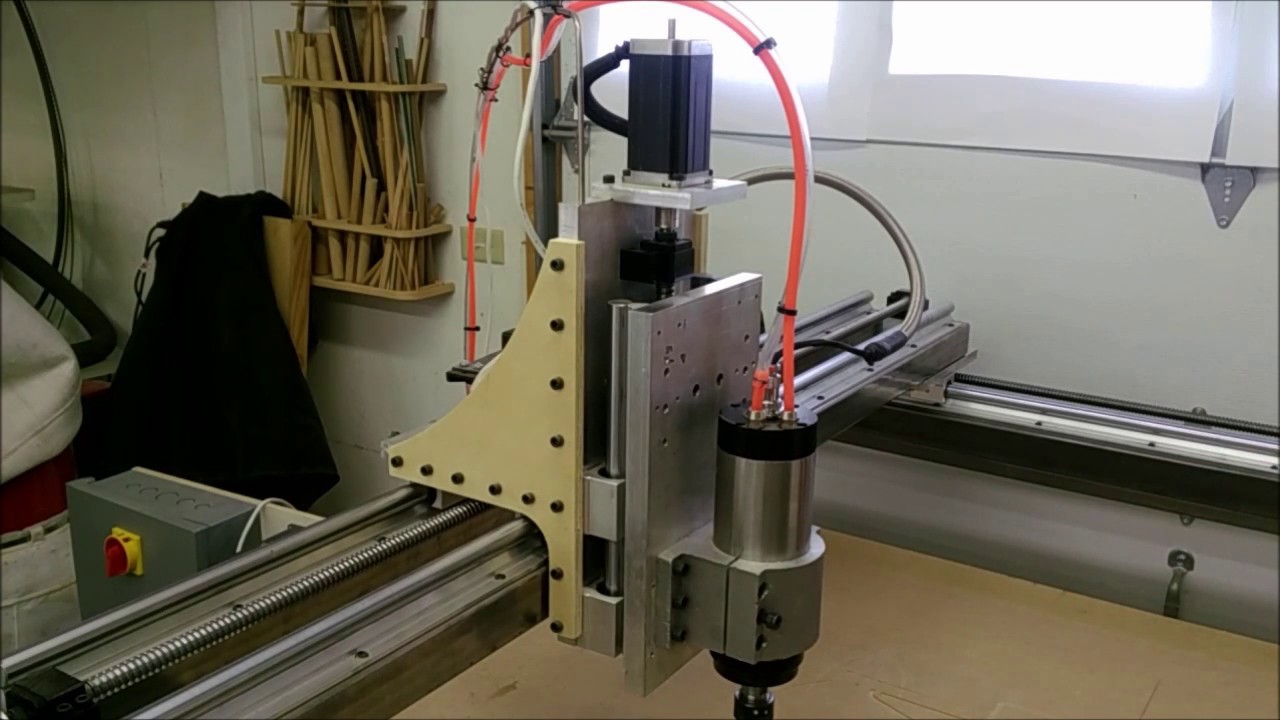

This is a very good router that can be built at a reasonable price using readily available materials.

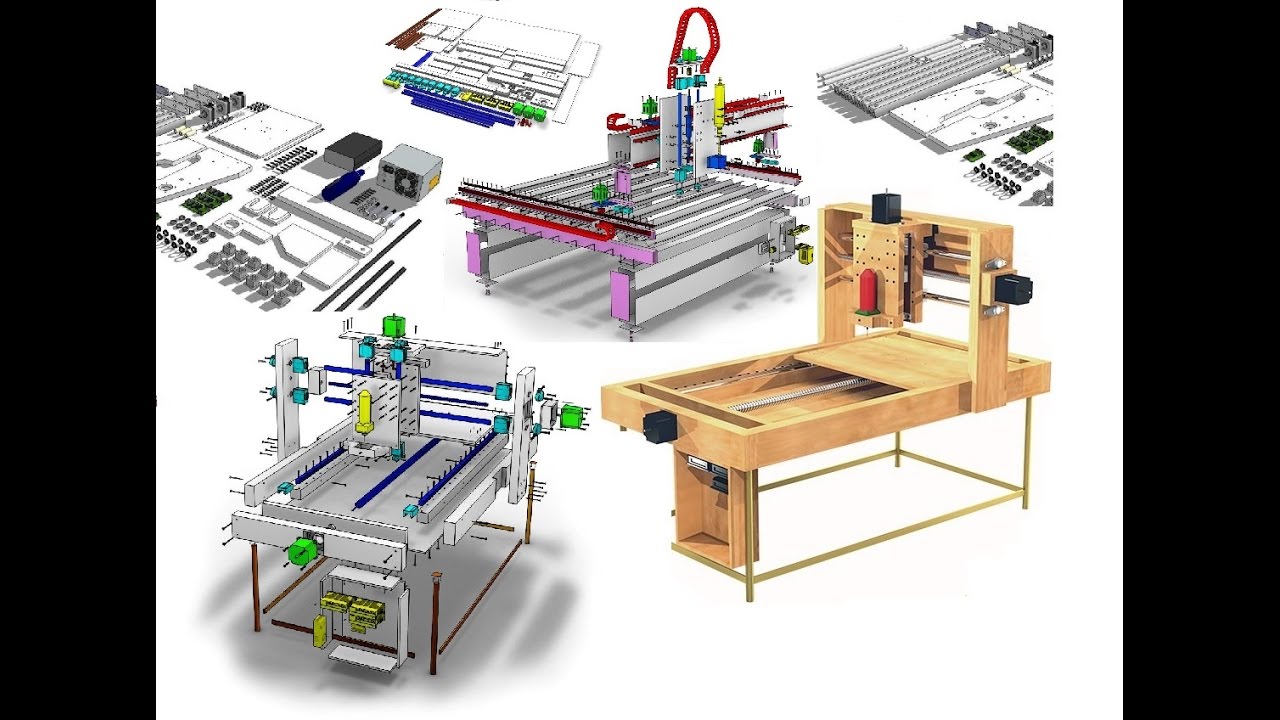

How to build a cnc woodworking machine. The Design and CAD Model. It all started with a proper design in my case a few sketches to get a good feeling for the dimensions and shape. The full form of CNC is computer numeric control.

Now that Im retired I have time to create things that Ive always wanted to like this CNC milling machine. Nevertheless the key steps to build your own CNC machine will generally be as follows. These plans document all the steps I followed to make my DIY CNC Router.

Ad Unlimited access to Woodworking Machinery market reports on 180 countries. Tap into millions of market reports with one search. This is the second DIY CNC Router I made after learning a lot from building the first version.

The exact assembly of your CNC machine will depend on the type of machine you choose to build the custom options you choose what you plan on making with the machine and many other factors. Build Your Own CNC Milling Machine. If you plan to design your own machine I recommend a parametric CAD-modeling tool.

Quickly after the sketching phase came the CAD model. Learn how to build a cnc woodworking machine in an afternoonFor instant acess go here. Ad Unlimited access to Woodworking Machinery market reports on 180 countries.

Building your own 3-Axis CNC router is both fun and educational. Tap into millions of market reports with one search. Best tips and tricks on how to build a CNC woodworking machine.