How Do You Make A Sharpening Jig For Wood Turning Tools

Focus on removing an equal amount from both faces so that the point remains centered on the tool.

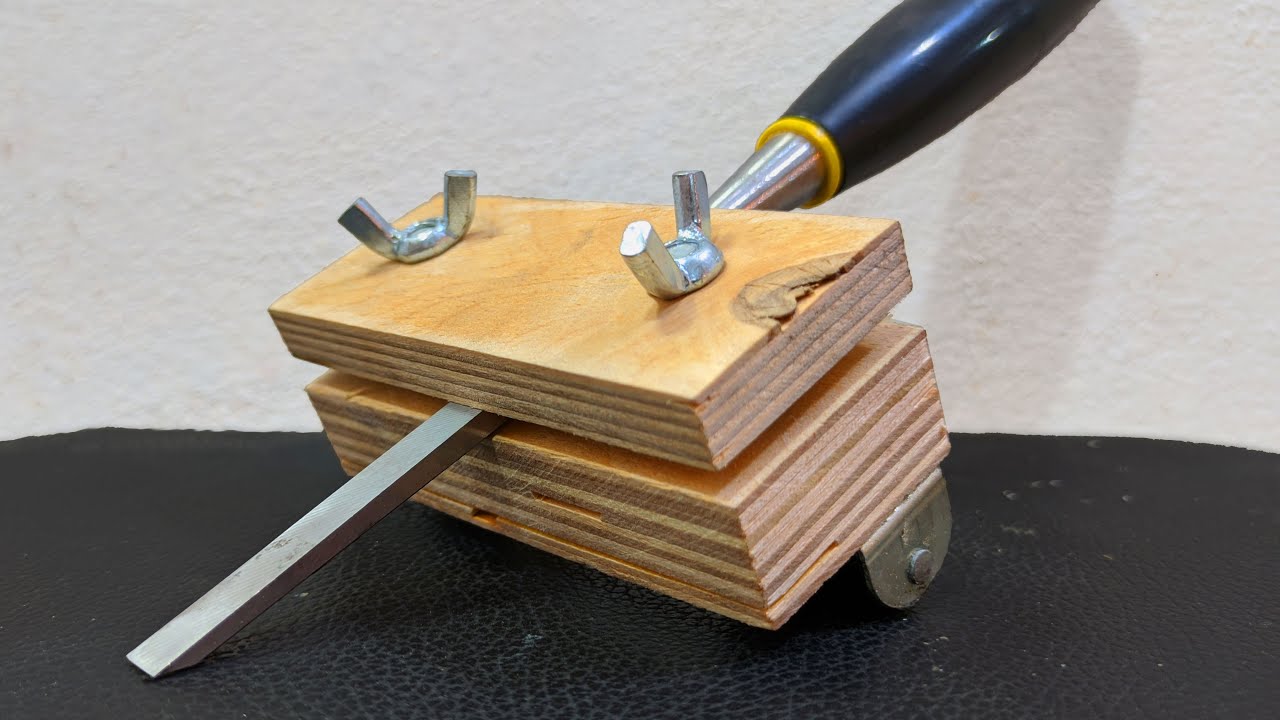

How do you make a sharpening jig for wood turning tools. The video is a bit choppy. I forgot to take a picture of this step but you can see them in this picture as well. DONE - DIY wood version of Wolverine jig for sharpening lathe gouge tools on bench grinder Wood turning Woodworking projects that sell Wood turning projects.

This will remove any debris on the grinder. The end result should be the point of the parting tool be ground to a sharp squared of point. Also after cutting you might want to file all the sharp edges.

You can either have the supplier cut the steel or do it yourself. Dressing the grinder involves using a diamond sharpening tool. I will show you how you can build a really cheap and simple DIY sharpening jig for shop grinders to sharpen your woodturning chisels and any other woodworki.

Insert the tool in a 45 degree holder. To sharpen adjust the flat tool rest so that the tools bevel angle matches the wheel. You want to remove that debris and prepare your grinder for the optimum sharpening of your lathe tool.

Just ignore those bits in the middle I then bolted the Grinder to the top board centered it as best I could. Compare Pricing Distributors Save. 516 nuts - at least 4 for the jig.

Grind the wing on one side then the other taking care to keep their tops level and at the required sweep angle. I screwed 2 sections of 10 oak to the ends of the bottom board this would be for supporting the outside edges. With the end of the holder in the jig arm adjust the arm until the tool meets the wheel at 45 degrees.