Explain The Different Types Of Cutting Tools

Ii Thermal Cracking and Tool Fracture.

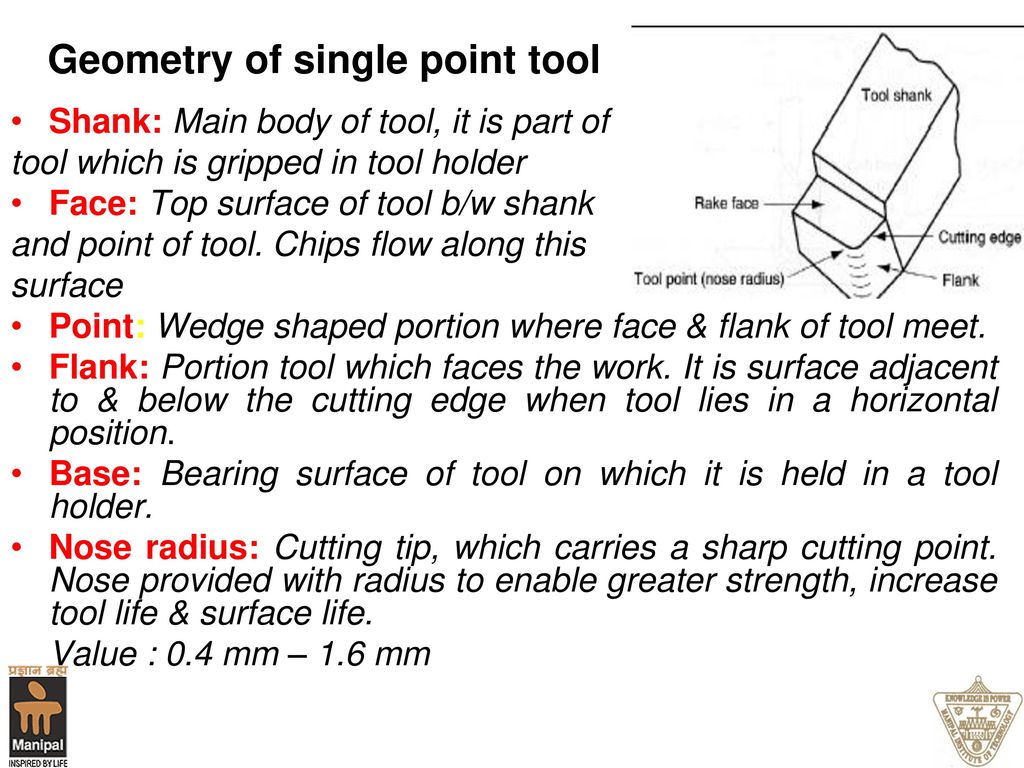

Explain the different types of cutting tools. For example low carbon steel aluminum and copper. Semi-automatic and automatic improves cutting room productivity and improves cutting accuracy. Single -Point Cutting Tool.

That means the body of the cutter is composed of some different materials whereas its cutting portion is developed from some other material. These two portions of the cutting tool can be conjoined by following any process including clamping welding and so on. Forms of Tool Wear.

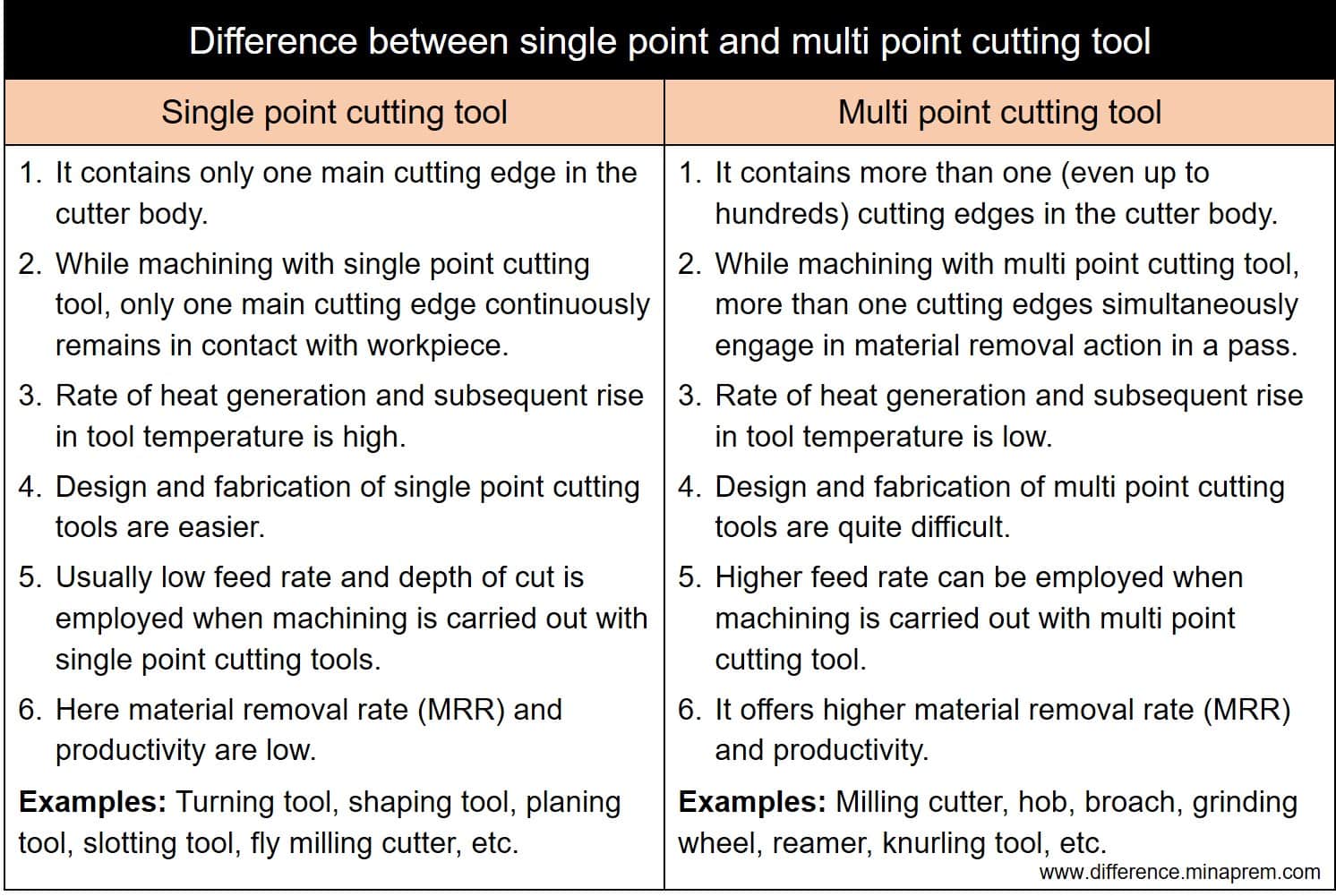

Fine tooth blades come in different sizes. Flank and crater wear are very common type of wears. 29-3 Cutting Tools One of most important components in machining process Performance will determine efficiency of operation Two basic types excluding abrasives Single point and multi point Must have rake and clearance angles ground or formed on them.

Built-up edge means the adhesion of work material on the rake face of the cutting tool near the cutting edge. Some Cutters with Description 1. High speed steel is very common tool material which is an alloy of steel tungsten Chromium and Vanadium.

This cutter is developed from various types of materials. These are two of the most prevalent milling operations each using different types of cutters the and mill and the face mill. It occurs frequently while machining softer or ductile metals at lower cutting speeds.

Slide and face cutter. Different types of cutting machines and equipment are available for cutting fabrics and machines are used as per requirement and production volume. The wear amount of friction with various metal and non-metal materials is only 150-1800 of cemented carbide which is the most ideal material for cutting tools.